Brother MFC-9140CDN User's Guide Page 42

- Page / 234

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

Chapter 2

32

Envelopes 2

The machine is designed to work well with

most envelopes. However, some envelopes

may have feed and print quality problems

because of the way they have been made.

Envelopes should have edges with straight,

well-creased folds. Envelopes should lie flat

and not be of baggy or flimsy construction.

Use only quality envelopes from a supplier

who understands that you will be using the

envelopes in a laser machine.

Envelopes can only be fed through the

manual feed slot.

We recommend that you print a test envelope

to make sure the print results are what you

want.

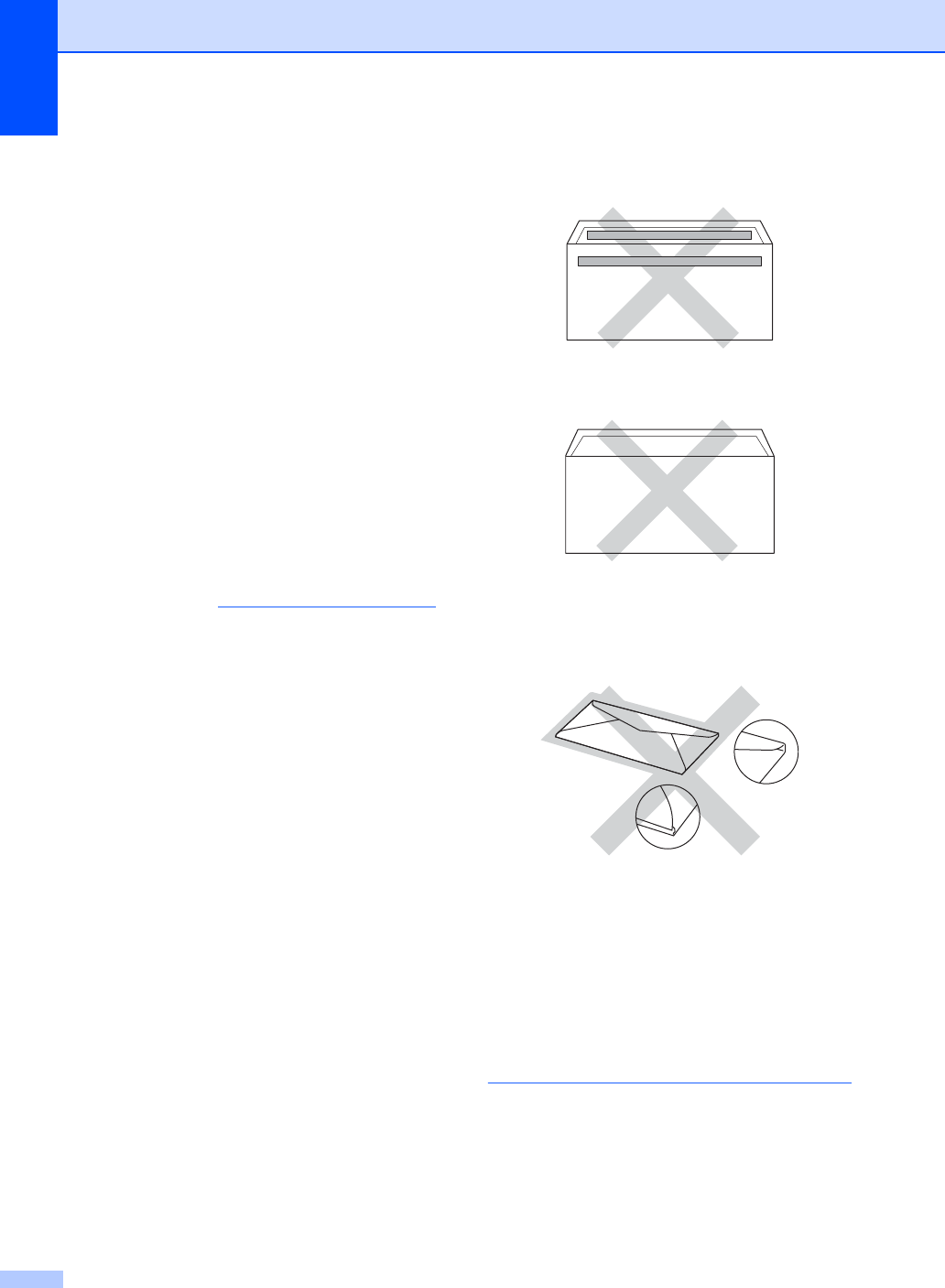

Types of envelopes to avoid 2

IMPORTANT

DO NOT use envelopes:

• that are damaged, curled, wrinkled or

an unusual shape

• that are extremely shiny or textured

• with clasps, staples, snaps or tie

strings

• with self-adhesive closures

• that are of a baggy construction

• that are not sharply creased

• that are embossed (raised writing)

• that were previously printed by a laser

or LED machine

• that are pre-printed on the inside

• that cannot be arranged neatly when

stacked

• that are made of paper that weighs

more than the paper weight

specifications for the machine

• with edges that are not straight or

consistently square

• with windows, holes, cut-outs or

perforations

• with glue on the surface as shown in

the figure below

• with double flaps as shown in the figure

below

• with sealing flaps that are not folded

down when purchased

• with each side folded as shown in the

figure below

If you use any of the types of envelopes

listed above, they may damage your

machine. This damage may not be

covered under any Brother warranty or

service agreement.

Occasionally you may experience paper

feed problems caused by the thickness,

size and flap shape of the envelopes you

are using.

- Basic User’s Guide 1

- 4 Sending a fax 36 6

- 5 Receiving a fax 39 6

- 6 Using PC-FAX 47 6

- A Routine maintenance 70 8

- B Troubleshooting 113 8

- D Specifications 207 9

- E Index 220 9

- Table of Contents 10

- General information 1 11

- Chapter 1 12

- Accessing the 13

- Advanced User’s 13

- Guide, Software User’s 13

- Guide and Network 13

- User’s Guide 13

- How to access the 15

- User’s Guides for 15

- Advanced Features 15

- Accessing Brother 16

- Support (Windows 16

- Support (Macintosh) 1 16

- General information 17

- Control panel overview 1 18

- Touchscreen LCD 1 20

- Settings screen 1 22

- Setting the Ready screen 1 23

- Basic Operations 1 24

- Shortcut Settings 1 25

- Adding Scan Shortcuts 1 26

- Adding Web Connect 28

- Shortcuts 1 28

- Changing Shortcuts 1 29

- Editing Shortcut Names 1 29

- Deleting Shortcuts 1 29

- Recalling Shortcuts 1 29

- Volume settings 1 30

- Loading paper 2 31

- Chapter 2 32

- Loading paper in the manual 33

- Loading paper 35

- Paper settings 2 38

- Acceptable paper and 39

- Handling and using special 41

- Loading documents 3 44

- Using the scanner glass 3 45

- Sending a fax 4 46

- Stop faxing 4 47

- Faxing Letter size documents 47

- Cancelling a fax in process 4 47

- Transmission Verification 48

- Report 4 48

- Receiving a fax 5 49

- Press Receive Mode 50

- Using receive modes 5 51

- Receive Mode settings 5 52

- Fax Detect 5 53

- Fax Preview 54

- (Black and White only) 5 54

- How to print a fax 5 55

- Turning off Fax Preview 5 56

- Using PC-FAX 6 57

- PC-FAX Send 6 58

- Telephone line 59

- Connecting an external 60

- External and extension 61

- Operation from external or 62

- For Fax/Tel mode only 7 62

- Using extension telephones 62

- (U.K. only) 7 62

- Using a non-Brother cordless 63

- Using Remote Codes 7 63

- Turning on the Remote Codes 7 64

- Changing the Remote Codes 7 64

- How to dial 8 65

- Storing numbers 8 66

- Changing Address Book 67

- Making copies 9 68

- Copy Options 9 69

- MFC-9330CDW and 70

- MFC-9340CDW) 70

- Printing data directly 71

- Printing a document 11 74

- How to scan to a computer 12 75

- ControlCenter4 (Windows 76

- Click File 77

- Press Scan 77

- Touchscreen 12 78

- How to scan to a computer 79

- Routine maintenance A 80

- Replacing the toner 84

- Replacing the drum units A 91

- Replacing the belt unit A 97

- Replacing the waste toner 101

- IMPORTANT 102

- Routine maintenance 103

- Cleaning and Checking 106

- Cleaning the outside of the 107

- Cleaning the LED heads A 108

- Cleaning the scanner glass A 109

- Cleaning the corona wires A 110

- Cleaning the drum unit A 113

- Cleaning the paper pick-up 119

- Calibration A 120

- Auto Registration A 121

- Frequency 122

- (Colour Correction) A 122

- Troubleshooting B 123

- Scanning problems: 124

- Journal report B 133

- Document Jams B 135

- Removing small documents 136

- Document is jammed at the 136

- Paper Jams B 137

- Paper is jammed at the back 139

- Paper is jammed inside the 141

- Troubleshooting 143

- Paper is jammed underneath 144

- Paper handling difficulties 147

- Printing received faxes 148

- Telephone line or connections 148

- Receiving Faxes 149

- Sending faxes 150

- Receiving Faxes (continued) 150

- Handling incoming calls 151

- Copying difficulties 151

- Sending faxes (continued) 151

- Scanning difficulties 152

- Software difficulties 152

- Network difficulties 153

- Other difficulties 154

- Setting Dial Tone detection B 155

- Improving the print quality B 156

- EFGHIJKLMN 165

- Machine Information B 166

- How to reset the machine B 167

- Using the Settings 168

- Settings Tables C 169

- All settings C 171

- Settings and features tables 173

- Features Tables C 190

- Options (to OCR) C 200

- Options (to USB) C 202

- Options (to E-mail Server) C 204

- Toner C 211

- Wi-Fi Setup C 211

- Web (More screen) C 212

- Shortcut C 213

- Entering text C 216

- 410 mm 483 mm 217

- Document Size D 219

- Print media D 220

- Scanner D 223

- Printer D 224

- Interfaces D 225

- Network D 226

- Direct Print feature D 227

- Computer requirements D 228

- Consumable items D 229

(71 pages)

(71 pages)

Comments to this Manuals